September 3, 2025

What Is a PLC?

A programmable logic controller (PLC) is a rugged, industrialized computer used to automate production line processes and adjust machinery settings in real time.

PLCs got their start in the late 1960s with Richard E. Morley’s Modular Digital Computer (Modicon), which was a semiconductor-based solution created to replace complex hardwired relay systems.

Reductions in semiconductor size, paired with advanced networking solutions, gave rise to the modern PLC.

This allowed manufacturers to streamline production processes by ingesting real-time data inputs and taking immediate action based on programmed logic.

Key functions of PLCs include logic operations, timing, and counting.

Today, most manufacturing firms use PLCs to help manage production lines, but many companies aren’t sure exactly how these devices work or how to get the most from their PLC infrastructure.

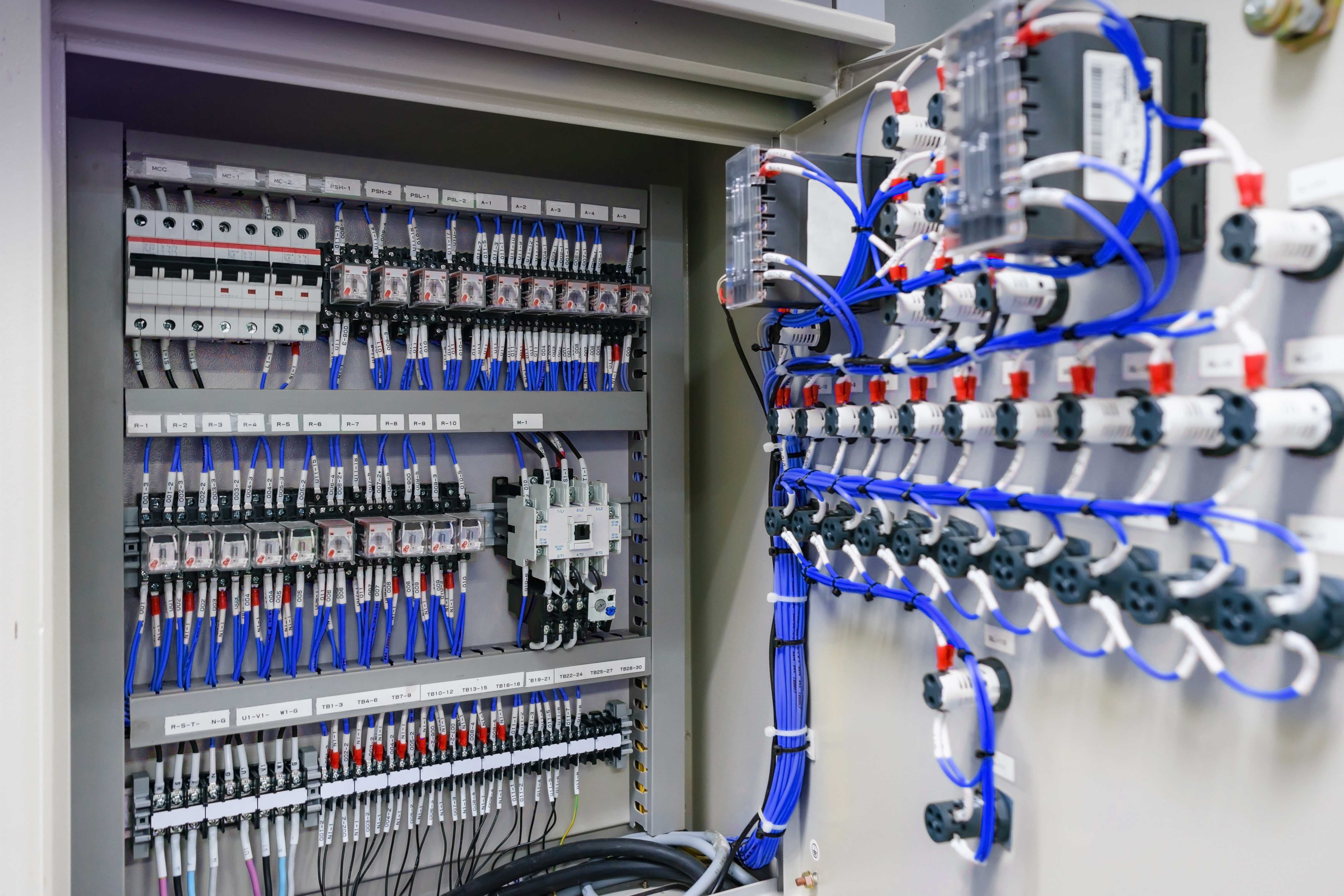

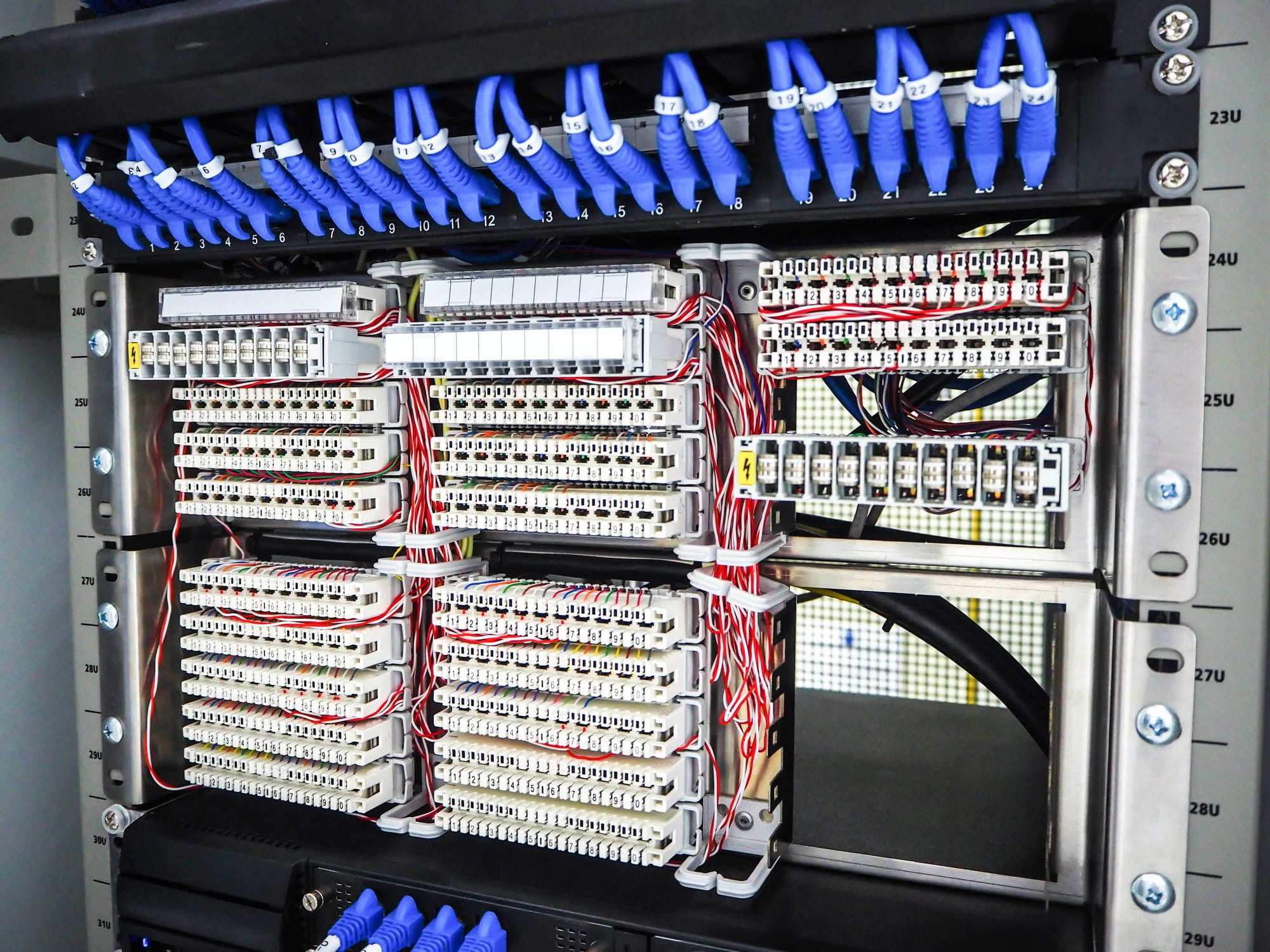

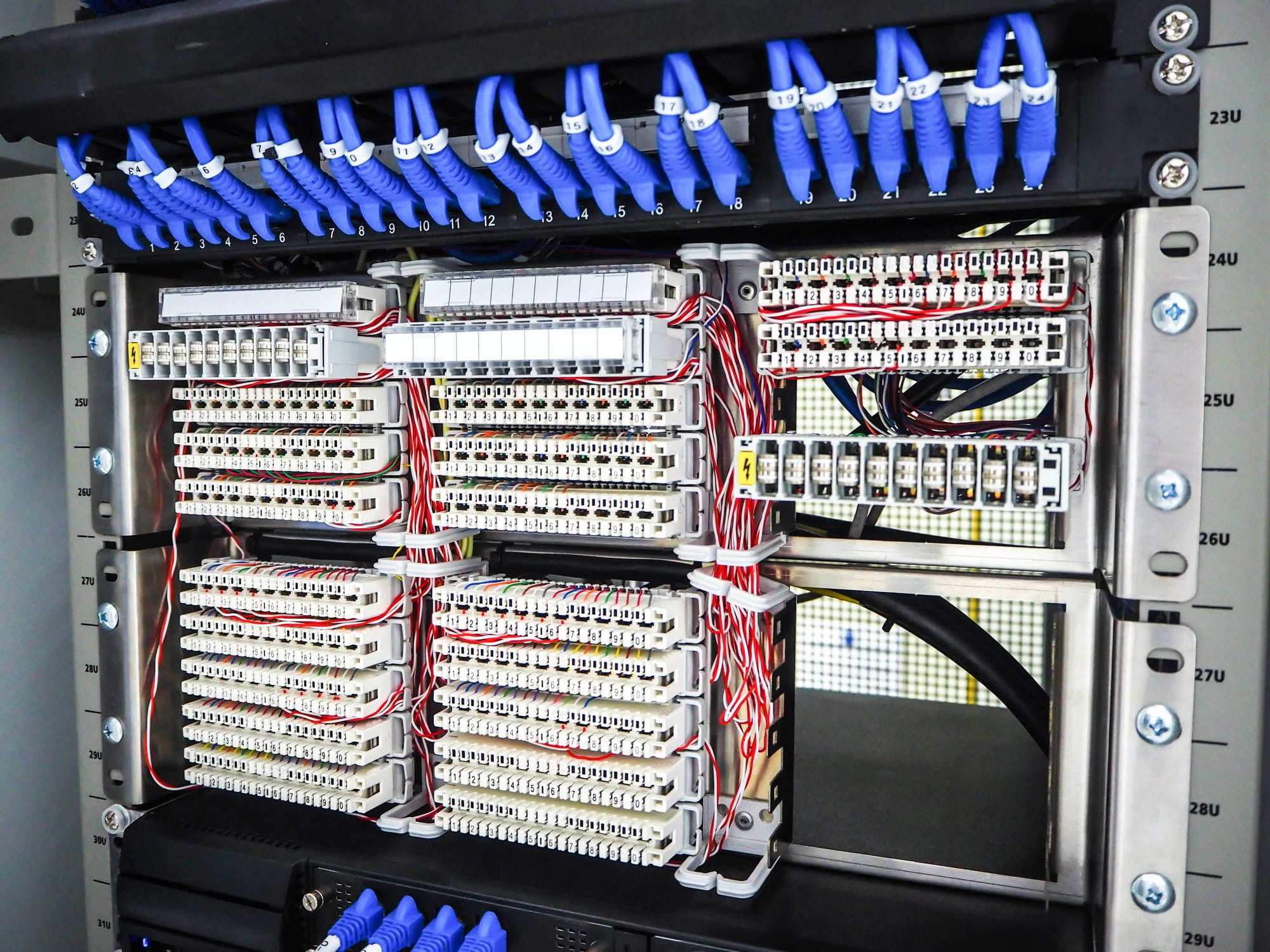

Key Components of PLCs

Programmable logic controllers can come in many shapes and sizes. Some are small enough to fit in your hand, while others require large-scale fixed mounts. Regardless of their form or function, however, all PLCs share four common components:

Input/output (I/O) modules: For a PLC to function, it must be able to ingest data and send instructions to connected devices. This is accomplished using I/O modules. Inputs are collected and sent to the CPU, where they are processed and delivered as outputs.

I/O modules may be analog or digital. Digital modules use discrete states, such as on/off or up/down. Analog modules, meanwhile, capture inputs and provide outputs along a continuous scale.

Central processing units (CPUs): CPUs contain the programming logic of a PLC system. They store and process the data provided by input models and then send instructions to output modules, which translate these instructions into machine-ready formats.

Power supplies: PLCs require constant power to operate. Many include both a hardwired and a backup power supply to reduce the risk of unexpected failure.

Human machine interfaces (HMIs): HMIs allow users to interact with PLCs. These interfaces may be simple display screens with keypads or more advanced touchscreens that allow more granular control.

PLCs may also leverage communication ports or protocols to provide real-time updates on machine status.

What Sets PLCs Apart

While PLCs share some characteristics with microcontrollers and PCs, they fulfill a different function. Microcontrollers are embedded systems; they exist as hardwired components within other devices. PLCs, by contrast, are standalone devices that can be connected to one or more systems.

Personal computers are also programmable, but they don’t connect directly to industrial machinery. In large part, this is because they are not designed to withstand the rigors of a production line. PLCs, meanwhile, are ruggedized to ensure continued operation in harsh environments.

Integration of PLCs With Other Automation Systems

For PLCs to be effective, they must integrate with other systems and share information. Consider a PLC designed to monitor chemical processing machinery that mixes components to produce specialized materials.

If input data analyzed by the CPU shows the machine is experiencing higher-than-average pressure values, the PLC program can produce an output that activates value systems to resolve the issue.

While this action is beneficial on its own, it becomes more valuable when paired with software solutions such as CMMS or ERP tools, or when connected to supervisory control and data acquisition (SCADA) systems.

As a result, manufacturers must prioritize both PLC implementation and integration with other automation systems.

This practice also helps companies leverage the Industrial Internet of Things (IIoT) in daily operations. Put simply, the IIoT refers to connected devices that allow organizations to monitor, manage, and modify industrial processes more effectively.

A simple IIoT network might include wired and wireless sensors that capture machinery data and feed it to a PLC. From there, the PLC makes logic-based decisions, takes action to resolve any issues, and sends data to CMMS tools and SCADA systems, making it available via HMIs. The result is an interconnected, observable network that improves performance and reduces risk.

Benefits of Using PLCs in Manufacturing and Process Control

Programmable logic controllers strengthen manufacturing and process operations by improving flexibility, scalability, reliability, and safety.

When properly configured, PLCs help plants adapt to new equipment, expand capacity, maintain uptime during faults, and respond quickly to abnormal conditions—making them a foundational element of modern industrial control.

FlexibilityA PLC program can be rewritten as needed to interact with new machinery or implement new functions. |

ScalabilityModular PLCs can be expanded to help business growth. Instead of an all-in-one approach, modular PLCs start with a base CPU that can be expanded using I/O, HMI, and communication modules. |

ReliabilityFault-tolerant PLCs can continue operating even if some functions are compromised. This reduces the impact on production line performance while technicians diagnose and address the issue. |

SafetyPLCs can be programmed to take specific actions in response to safety risks. For example, if a PLC detects a sudden temperature spike in a high-pressure machine, safety protocols may trigger a shutdown command to prevent escalation. |

Common Applications of PLCs in Various Industries

While PLCs are often used in manufacturing and processing, they are also being adopted across other industries.

One example is the use of “green” PLCs, which are designed to minimize energy consumption without negatively impacting functionality.

These PLCs are increasingly part of sustainability strategies in sectors such as energy, oil and gas, and technology.

Recent research suggests PLCs may enable improved energy management across multiple devices. This makes them well-suited for industries such as utilities, which require precise measurement, control, and delivery of electricity, gas, and water.

There’s also a growing market for AI-enabled PLCs, which aid proactive anomaly detection for predictive maintenance and adaptive process optimization.

Capitalizing on PLC Potential

PLCs play a central role in the management and automation of modern industrial systems and are a cornerstone of Industry 4.0, which combines physical operations with digital management to enable real-time insight.

While traditional PLCs remain in use across many industries, advances in semiconductor technology, precision I/O control, and artificial intelligence (AI) are enabling smarter, smaller, and more adaptable PLCs.

For many companies, this creates an inflection point.

While they recognize the value of PLCs in their operations, they may be unsure how to upgrade existing infrastructure or deploy new solutions at scale.

At EOSYS, we have the experience and expertise to help companies capitalize on PLC potential.

Our automation solutions and electrical control services support identifying areas for improvement, deploying best-fit solutions, streamlining integration, and monitoring systems over time to ensure sustained performance.

Empower your PLC environment. Let’s talk.