OT Networks

LEGACY SYSTEMS BECOME INSIGHT POWERHOUSES

When legacy systems and automation islands come together, you gain insights into performance and opportunity. Finding the right partner to design a secure, resilient Operational Technology (OT) network enables real-time decision-making and advanced analytics that unlock the full value promised by Industry 4.0 while driving efficiency and lasting results.

Digital Foundation

Your Next-Level Operation Starts Now

Digital transformation stalls when infrastructure can’t keep up. We help manufacturers connect legacy PLCs, SCADA, and equipment to secure platforms, unlocking real-time insights, faster decisions, and the confidence to lead with data.

Capabilities

Step Into Faster, Data-Driven Decision Making

Manufacturing data becomes your key competitive advantage with smart networking, powerful computing, and scalable analytics. Secure connections and real-time insights help you make intelligent decisions faster.

Edge Computing Integration

Transform raw production data into actionable insights at the source.

- Deploy analytics where data originates

- Reduce latency for critical decisions

- Enable AI and ML at the edge

Cloud Connectivity

Bridge shop floor operations with enterprise intelligence and external analytics platforms.

- Secure pathways to cloud platforms

- Real-time data streaming capabilities

- Scalable infrastructure for growing data needs

Advanced Analytics

Enable condition monitoring, predictive maintenance, and process optimization through connected systems.

- Sensor integration and data collection

- Machine learning pipeline support

- Automated alerting and response systems

- Prescriptive analytics for optimization algorithms

Partners

Building Your Network With Trusted Vendors

Every layer of industrial automation depends on clear accountability, solid expertise, and integration designed for your specific needs. We lead the design and execution, bringing you trusted partners to deliver flexible, secure control and network systems that keep your operations steady.

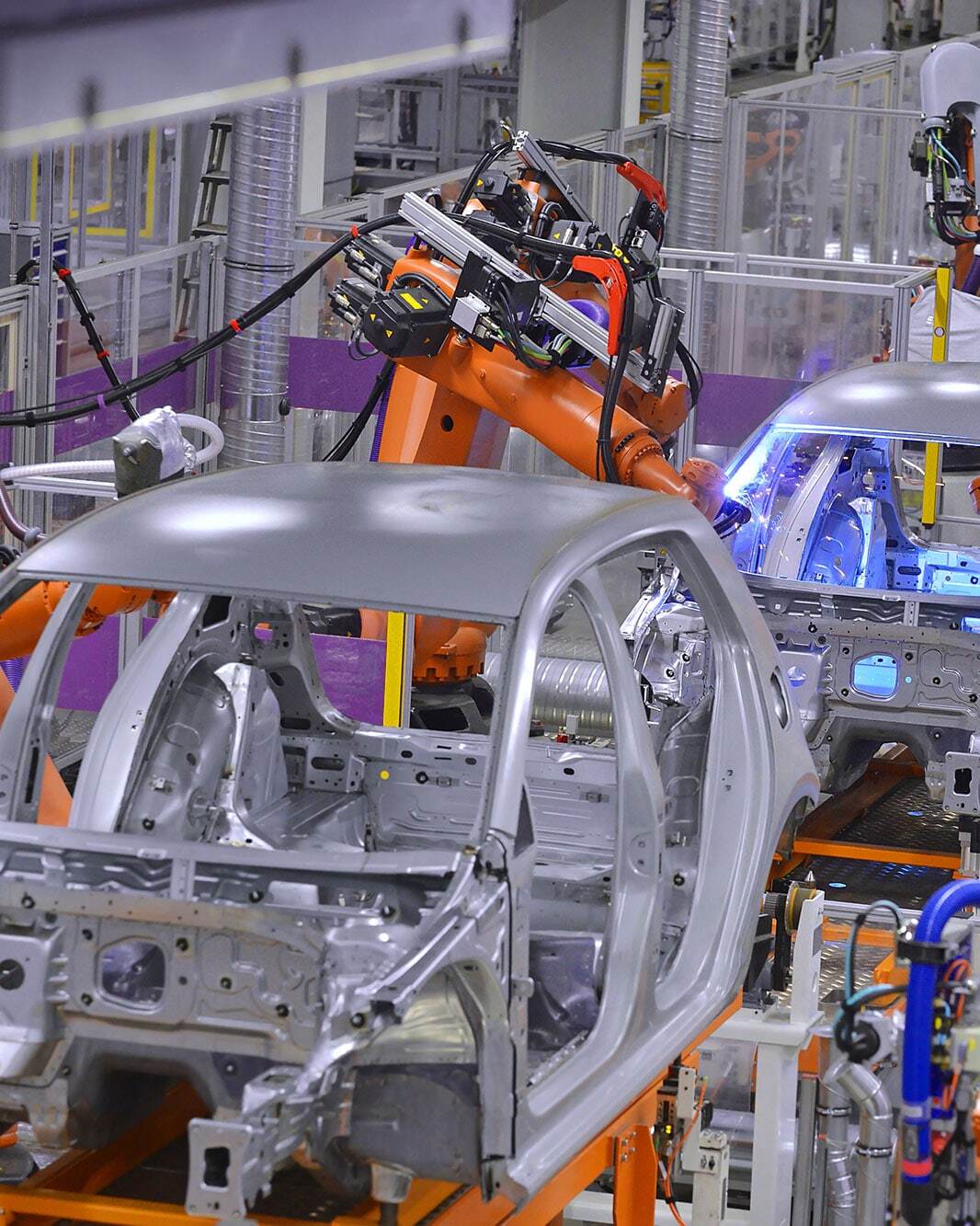

Case Study

Digitalization At Work: An Automotive Digital Transformation Success Story

When one of the most extensive vehicle manufacturing plants in the world needed to go digital, they engaged EOSYS to lead the charge based on our 20+ year relationship of successful projects together. They didn’t just need to remove paper, they needed to unlock additional efficiencies and business value.

Contact

Make Connections That Enable Real-Time Insights

FAQs

OT digitalization unlocks more efficient operations, improves data-driven decision-making, enables real-time visibility, and supports predictive maintenance for reduced downtime.

They bridge legacy assets with modern analytics, IoT, and AI, delivering real-time data from production equipment to business systems, fueling smarter decisions.

Unified networks streamline workflows, enable predictive and real-time analytics, reduce manual data entry, and simplify troubleshooting, boosting agility and transparency.

Edge computing transforms raw production data into actionable insights at the source, reduces latency, and supports AI/ML-driven optimization closest to operations.

- Higher efficiency and throughput

- Predictive and run-based maintenance (less downtime)

- Data-driven planning and scheduling

- Optimized inventory, quality, and resource utilization

- Continuous improvement with measurable ROI

- Integrating legacy and modern systems

- Ensuring data accuracy across the network

- Cybersecurity and compliance risks

- Cultural resistance and change management

Begin with measurable business goals (profitability, efficiency, customer experience). Pilot projects should target critical pain points, show rapid ROI, and scale up successful outcomes.

Connected OT networks improve material tracking, automate reordering, optimize logistics, and drive transparency, especially valuable for supply chain resilience.

KPIs include OEE (overall equipment effectiveness), cost per unit, labor reduction, real-time inventory, maintenance frequency, and speed of deployment.

Zero-trust segmentation, firewalls/DMZs, micro-segmentation, firmware signing, and proactive cybersecurity monitoring are critical for protecting connected assets.

It enables faster product launches, quality consistency, flexible manufacturing, and scalable analytics for deeper customer insights, resulting in a stronger market position.

- Conduct a digital maturity assessment

- Align stakeholders on business goals

- Select scalable and secure infrastructure

- Integrate continuous learning and improvement protocols

Automated monitoring, audit trails, and secured data flows simplify regulatory reporting, easing the burden on Mark’s team and protecting Ryan's brand reputation.