Electrical Control Solutions

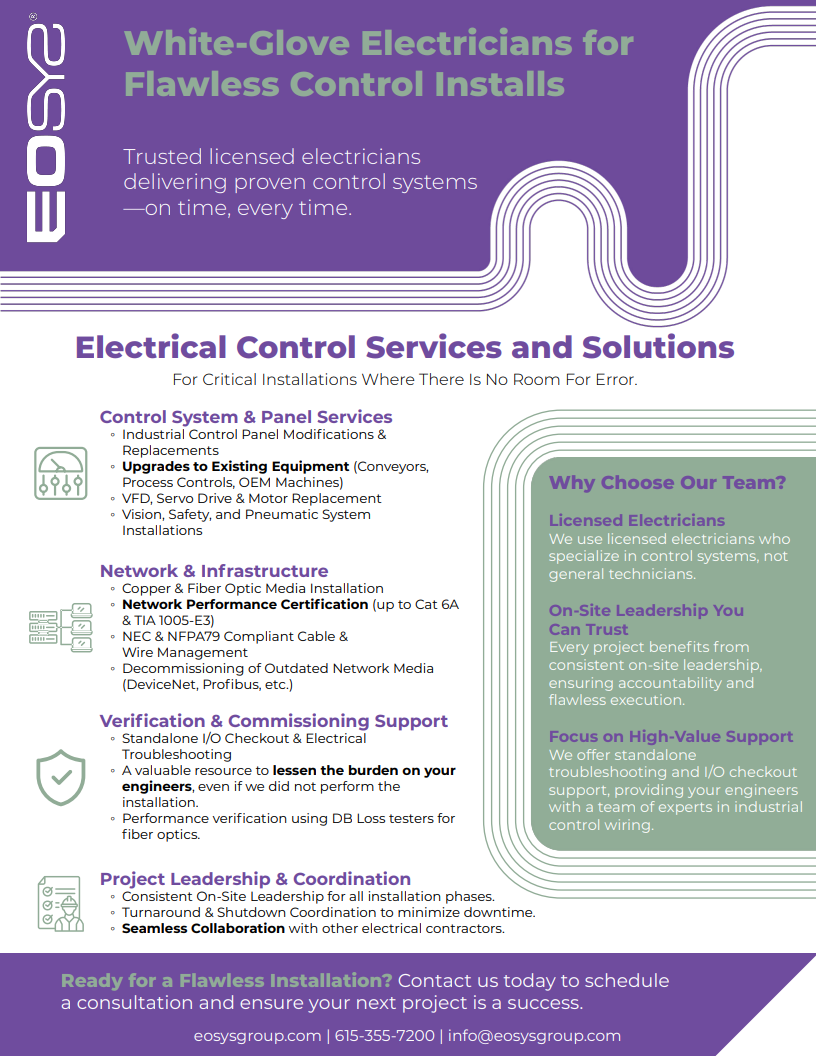

White-Glove Electricians for Flawless Installations

Keeping your plant efficient and compliant requires deep control system expertise. Our specialized, licensed electricians bring control system expertise to every installation, so you can stay focused on running your operation worry-free.

Capabilities

Built with Care

Wired for Your Success

For critical installations where there is no room for error, our white-glove industrial electricians are focused on precision in every connection. We deliver control solutions that enhance the reliability of your operations, so that your team can focus on growth and efficiency.

Control Systems & Panel Services

- Modifications and replacements

- Upgrades to existing equipment (conveyors, process skids, OEM machines)

- VFD, servo drive & motor replacement

- Vision, safety, and pneumatic system installations and upgrades

Network Infrastructure

- Copper & fiber optic cable installation

- Cable performance certification up to Cat 6A

- Complete or partial replacement of outdated network media

- Compliance with TIA and ISO standards for industrial telecom cabling infrastructure

Verification & Commissioning Support

- Standalone I/O checkout & electrical verification

- Electrical checkout and verification during commissioning phases

- Troubleshooting and resolution of punch list items

When There’s No Room for Error

Download our installation overview to help your control system installation run smoothly.

Industries

Precision-Controlled Outcomes

Your plan needs tailored installations and upgrades backed by decades of experience across industries. We perform custom installations and upgrades that combine electrical skill with controls expertise.

Contact Us

Put Control Back in Your Hands

FAQS

We specialize in manufacturing control systems, expertly translating your plans into faultless, production-ready installations that minimize downtime.

We start with daily work plans that align teams, tasks, and timelines, so nothing slips. Our build standards minimize hit list items, and our precise wiring, verification, and commissioning support catch issues early. That means fewer delays, smoother handoffs, and a project that stays on track.

Our team brings decades of experience across diverse sectors, including food and beverage, spirits, chemicals, automotive, pulp and paper, metals, CPG, power and utilities, and others.

We perform prework during production hours and schedule cutovers during planned maintenance outages to avoid downtime. Our team builds detailed installation plans that align with your operations and provides thorough commissioning and troubleshooting to ensure seamless integration.

Yes, we offer service through commissioning with electrical checkouts, standalone I/O verification, and punch list resolution. Our goal is simple: confirm everything works before handoff so your team can move forward with confidence.

Our scope includes copper and fiber optic cable installation, control cable termination, and decommissioning of outdated media.

Our team leads bring over 30 years of hands-on troubleshooting experience. We reduce the burden on your controls team by resolving issues quickly and ensuring reliable system performance, so your operations stay focused and productive.

Our electricians specialize in wiring that works because even the best plans fail without it. We ensure every connection is verified, aligned, and built to support production without error, so your systems perform reliably from day one.

Absolutely. We offer strategy discussions to align control system plans with your operational goals and set the stage for success.

We install and replace PLCs, HMIs, VFDs, servo drives, motors, vision systems, safety devices, pneumatic components, and more—delivering comprehensive control solutions built for performance and reliability.

We specialize in upgrading legacy control systems to modern platforms, improving visibility, control, and reducing downtime risks.

Through better control platform upgrades and clear wiring, operators gain faster, more reliable system feedback and control.

Yes. We upgrade conveyors, OEM machines, control panels, and more—tailored to your plant’s needs.

Our scope includes copper and fiber optic cable installation, certified testing to TIA an/or ISO standards, and decommissioning of outdated media.

Led by licensed electricians, our installations follow industry standards and client-specific compliance needs to maintain operational and safety certifications.