Case Studies

Learn From Those Leading the Way

Your peers aren't guessing. They're executing. Read on for stories of what's working and how you can make these ideas your own.

Revolutionizing Poultry Power

Carolina Poultry Power faced rising energy costs and sustainability challenges in its poultry operations. EOSYS guided them to transform waste into clean power, cutting energy expenses and emissions. This solution improved their efficiency and success, making them a leader in sustainable poultry energy.

Innovation Meets Legendary Craftsmanship

Just as tradition meets innovation in an iconic blend, Jack Daniel’s partnered with us to craft a future-ready legacy. Together, we distilled real‑time data, automated quality checks, and elevated collaboration. The result is smoother bottling, sharper insights, and a legendary brand poised to lead the industry.

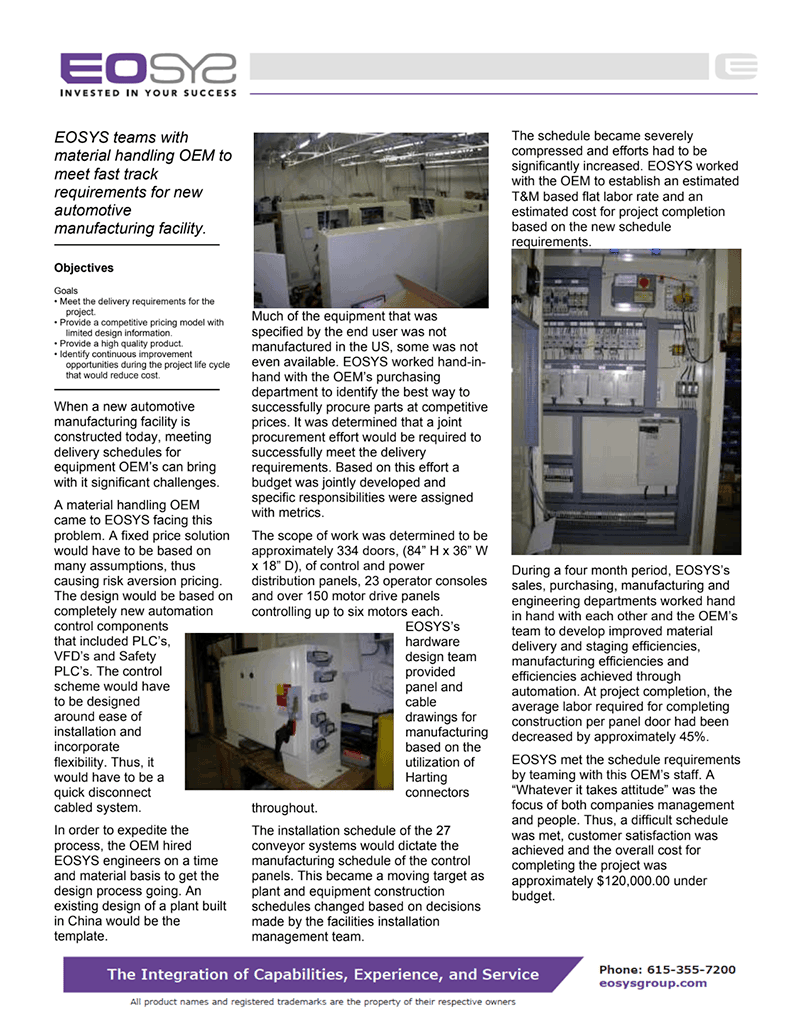

Three Months, Zero Compromise

A major automotive manufacturer faced a tight three-month deadline to integrate custom AGVs into its production line. EOSYS applied a rigorous project methodology and coordinated complex technologies. Prioritizing safety, dynamic safety zones ensured efficient, secure AGV operation.