Industrial Automation

Operate With Confidence and Clarity

It’s not just the equipment you see. We build the brains behind your manufacturing—the advanced systems you don’t see that deliver real-time insights and operational intelligence tailored to your needs.

Capabilities

From Vision to Value

Your success depends on turning complexity into clarity and purchase into payback. Our experts work beside you, guiding you with clear, actionable automation strategies. We design, build, commission, and support solutions that maximize uptime and deliver lasting value for your operation.

Comprehensive Automation Project Services

- Feasibility, architecture, and budgeting

- Scope development and RFQ support

- System, electrical, MCC, and safety design

- PLC, DCS, HMI, historian, and MES programming

- Factory acceptance testing (FAT) and simulation

- Installation coordination, I/O, and loop checks

- Commissioning, site acceptance testing (SAT), and startup

- Training, production support, and ongoing maintenance

Automation Solutions

Trusted Guide for Your Automation Journey

Controls Design & Programming

Your controls are the foundation of your operation. We guide you in designing and programming a robust, scalable controls strategy—so your equipment performs precisely, reliably, and exactly as intended, every time.

- System Specification & Design

- Discrete, Process, and Motion Control Programming

- Advanced Process Control (APC)

- System Simulation & Factory Acceptance Testing (FAT)

HMI Design & Configuration

Empower your operators with clear, intuitive, and powerful interfaces. A well-designed HMI provides critical operational insight, simplifies complex tasks, and allows your team to make faster, smarter decisions on the plant floor.

- System Specification & Design

- High-Performance Graphics Development

- Process Data Acquisition & Historian Integration

- Custom Driver & Interface Development

- System Simulation & Testing

Process Design & Configuration

Optimize your facility's output by refining the very processes that create your products. We help you implement and configure systems that give you consistent, repeatable control for superior quality and efficiency.

- Supervisory and Regulatory Process Control

- S88 Batch Programming & Management

- Data Acquisition & Reporting Solutions

- Connectivity to 3rd Party Devices

Machine Safety

Protect your most valuable asset—your people. We guide you through the complexities of machine safety standards to design and implement systems that reduce risk, ensure compliance, and create a safer working environment.

- Guidance from Certified Functional Safety Engineers

- Hardware & Software Safety Design

- Functional Requirements Specification

- Safety Function Verification & Validation

Awards & Certifications

Leading with Purpose

Accolades and trusted certifications reflect more than technical skill. They let you know you're in good hands - with a team focused on driving exceptional performance for you and your business.

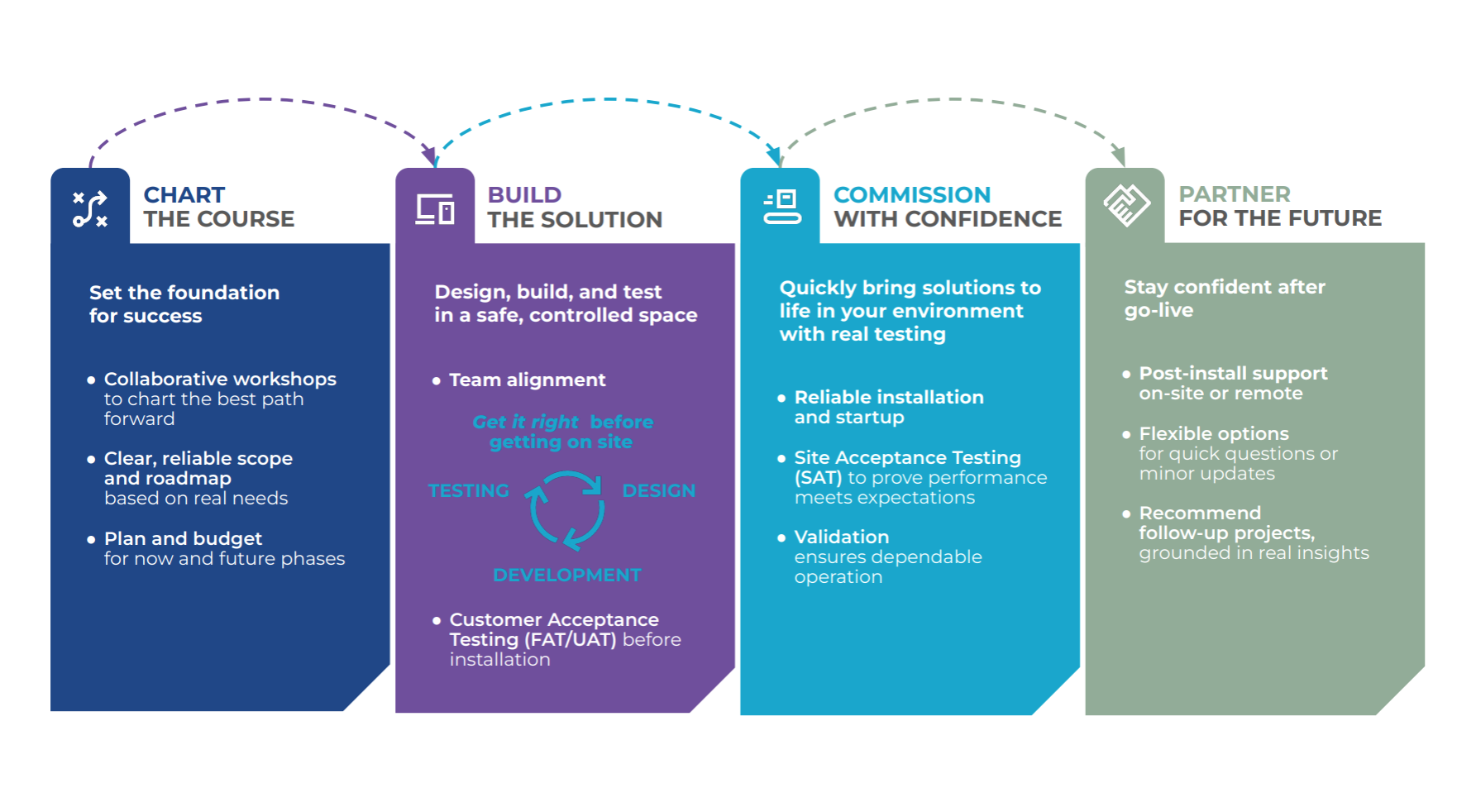

Our Proven Process

Clear Focus. Lasting Impact.

Rapid change and complex obstacles challenge industrial manufacturing every day. With over 30 years of experience and more than 15,000 projects completed, EOSYS delivers industrial automation systems designed and deployed for today’s realities. Our solutions increase uptime, streamline workflows, and provide lasting operational value.

Partners

Deep Bench, Stronger Results

Your automation complexity demands custom solutions. Our experts integrate industry-leading technologies to build systems tailored to your unique challenges.

When you choose EOSYS, you join clients who have benefited from over 30 years of hands-on experience and more than 15,000 completed projects. Independent evaluations confirm our commitment to delivering exceptional service and ongoing support.

Industries

Designed Around Your Unique Needs

Improve uptime, safety, and precision with automation systems built for your unique challenges. Our expert integration services connect every process and control point, boosting reliability and reducing downtime, so your plant performs at its peak every shift.

Contact

Build Resilience. Boost Performance.

FAQS

Common hurdles include integrating new systems with legacy equipment, managing downtime during installation, ensuring cybersecurity, and aligning automation goals with business objectives.

PLCs and HMIs are tailored specifically to operational workflows and control strategies, enabling seamless integration with existing systems and optimized functionality.

Key success factors include clear project scope, thorough planning, stakeholder alignment, phased implementation, and selecting experienced partners.

Automation typically boosts uptime, reduces errors, enhances quality control, increases throughput, and improves worker safety.

Tailored solutions address unique operational needs and industry compliance, often resulting in higher long-term reliability and return on investment.

Real-time data enables predictive maintenance, process optimization, and faster decision-making that drives continuous improvement.

Careful scheduling, extensive pre-commissioning testing, and phased rollouts help maintain production continuity and reduce risk.

Strong segmentation, access controls, regular updates, and continuous monitoring are essential to protecting against cyber threats.

Automated logging, process control, and audit trail generation simplify meeting industry standards and passing inspections.

ROI depends on project size and complexity, but it generally results in reduced downtime, labor savings, improved quality, and increased capacity.

Avoiding unclear objectives, underestimating integration complexity, neglecting cybersecurity, and poor change management are frequent pitfalls.

Flexible, scalable automation systems can quickly adjust production to new products, volumes, and quality or requirements.

Sectors with complex, regulated, or high-precision processes, such as food and beverage, chemicals, and pharmaceuticals, see significant gains.

Automation includes smart control, data integration, and decision-making capabilities, beyond just replacing manual labor with machines.

Yes, energy-efficient controls and optimized processes help lower resource consumption and waste.

Strong project management ensures the maintenance of scope, deadlines, budgets, quality standards, and stakeholder communication.

Early involvement is crucial to identifying risks, aligning design with goals, and ensuring smooth integration with existing processes.

Advances like IIoT, AI-driven analytics, edge computing, and more collaborative robotics are driving new capabilities and efficiencies.

The CSFD serves as a critical blueprint, defining the system's operational logic, control sequences, and safety interlocks to ensure all project stakeholders are aligned.