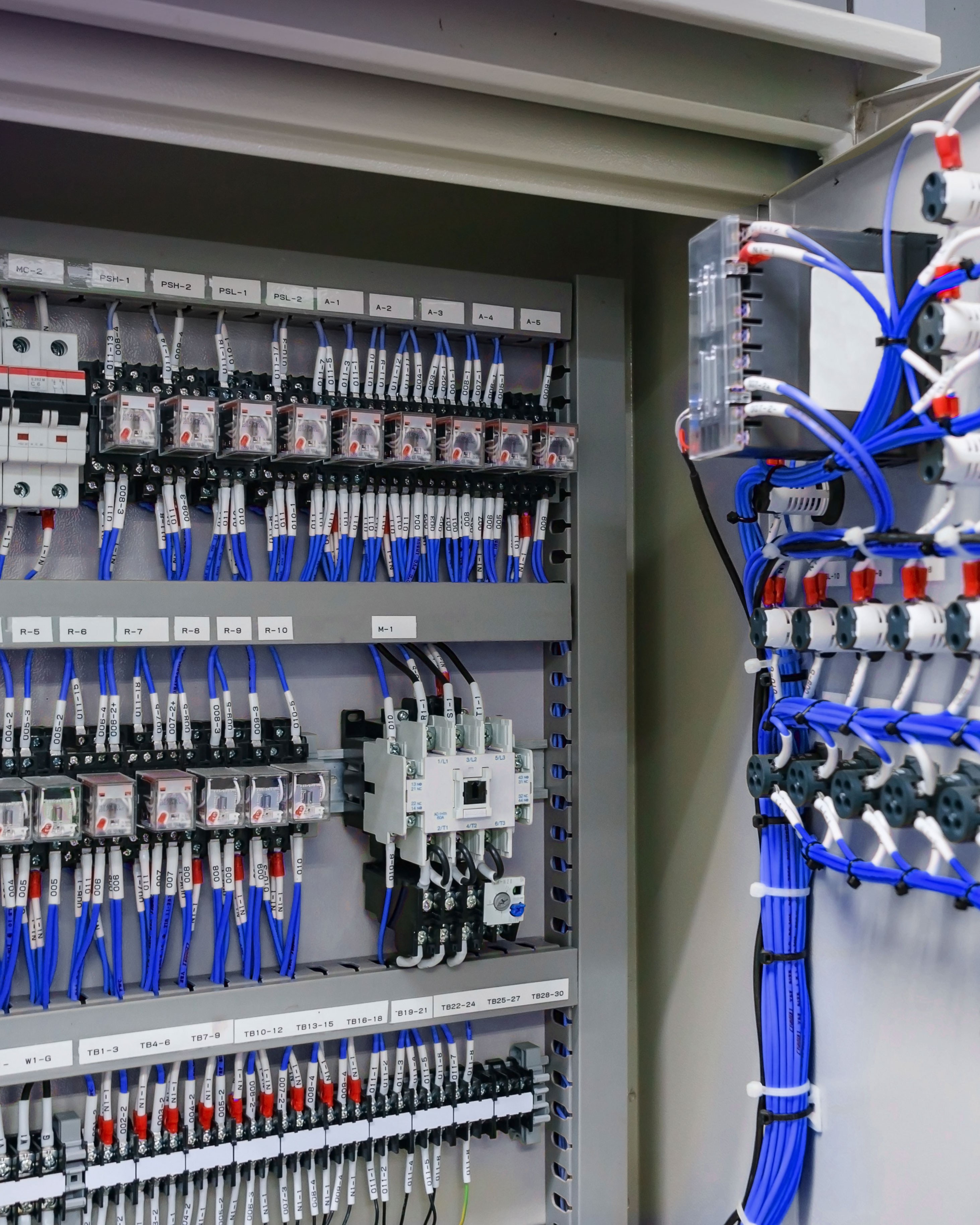

Industrial Panel Fabrication

Built to Run,

Wired to Win

Drive operational excellence with control panels built to streamline workflows, prevent defects, and enhance safety. Our precision engineering takes your project from planning to launch, ensuring every detail supports reliable, efficient operations.

Certified Solutions

Tested and Ready to Perform

Mission-critical systems demand control panels that perform. Minimize downtime and compliances risks with trusted, industry-led solutions built, tested, and tailored to your specific needs for safe and uninterrupted startups.

Built to Meet Rigorous Standards

- NFPA-70, NFPA-79, UL508A, UL698A plus custom standards

- Full Factory Acceptance Testing (FAT) Panels for hazardous locations and cleanroom environments

- Certified and tested for safety and compliance

Tailored Design, Built for Reliability

- Discovery and detailed requirements mapping CAD design and bill of materials development

- Controls engineered to fit unique operational needs

Skilled Fabrication with Expert Execution

- Precision assembly ensured by strict quality controls

- Extensive testing with detailed documentation

- On-site commissioning and integration support

- Build-to-install services simplify deployment

- Automated assisted fabrication

- Multi-door panel build capabilities

Case Study

Turning Concepts into Market-Ready Products

We helped a global leader in digital automation and energy management transform early concepts into prototypes that accelerated development and enabled scalable growth.

Industries

Designed for Your Environment

Every industry faces its own unique challenges. With control panels designed for your environment, you avoid costly downtime, reduce compliance risk, and keep production moving at full speed.

Contact

Elevate Performance and Reliability

FAQs

Control panels must meet standards like NFPA-70, NFPA-79, UL508A, and UL698A, along with any customer-specified requirements, to ensure safety, reliability, and regulatory compliance.

This eliminates reliance on external suppliers. On-site milling enables precise, rapid fabrication of panel components like enclosures, cutouts, and mounting holes directly in-house, significantly reducing build cycles, quicker assembly, and faster delivery.

Specialized design protocols, materials, and assembly processes are implemented to meet environmental and safety standards unique to hazardous or cleanroom settings.

FAT involves comprehensive, pre-shipment testing of panels against defined requirements, verifying functionality, compliance, and performance before delivery.

Yes, designs are developed with modularity and expansion in mind, facilitating easy upgrades and increased capacity aligned with growth plans.

They provide detailed documentation and visualization to ensure accuracy, streamline procurement, and reduce errors during fabrication and assembly.

Rigorous inspection protocols, tested assembly processes, and certified workmanship ensure each panel meets strict quality standards.

Specialized teams oversee installation, testing, and integration at the client’s site to ensure smooth startup and operational reliability.

Precise design, adherence to standards, and thorough testing reduce failures and ensure safe, uninterrupted performance throughout the panel lifecycle.

Panels are designed with advanced controls, data visibility, and integration capabilities to connect with analytics and predictive maintenance systems.

Expert support ensures panels interface effectively with existing automation systems, including troubleshooting and programming adjustments.

Custom solutions are developed collaboratively, respecting exact operational, environmental, and regulatory demands.

Conformance minimizes regulatory risks, safety incidents, and insurance liabilities, while ensuring panels meet third-party inspection criteria.

Precision fabrication delivers more than uptime. Clean layouts, durable components, and built-in diagnostics reduce maintenance costs, prevent defects, and streamline troubleshooting. Modular design and scalable architecture support future upgrades, while integrated safety features protect your team and your bottom line.

Factory testing ensures early problem detection in a controlled environment, lowering on-site startup risks and commissioning times.

Deep industry knowledge helps anticipate operational challenges, optimize designs for performance, and ensure compliance from the outset.