Old and new often mix like oil and water, but sometimes the right emulsifying influence can smooth their relationship and get them to cooperate like whiskey and water.

Project Methodology

When Stakes Are High, Execution Matters Most

Complex projects don’t have to feel complicated. Our proven process keeps your team informed, your project on track, and your stress levels low. You can relax knowing we’ve got your back.

Operational Discipline

Your Challenges Become Triumphs

We help your team avoid surprises. By carefully managing scope, anticipating potential pitfalls, and aligning the right resources, we turn complex projects into predictable, successful outcomes, so you can focus on your goals with confidence, knowing we’re looking out for you every step of the way.

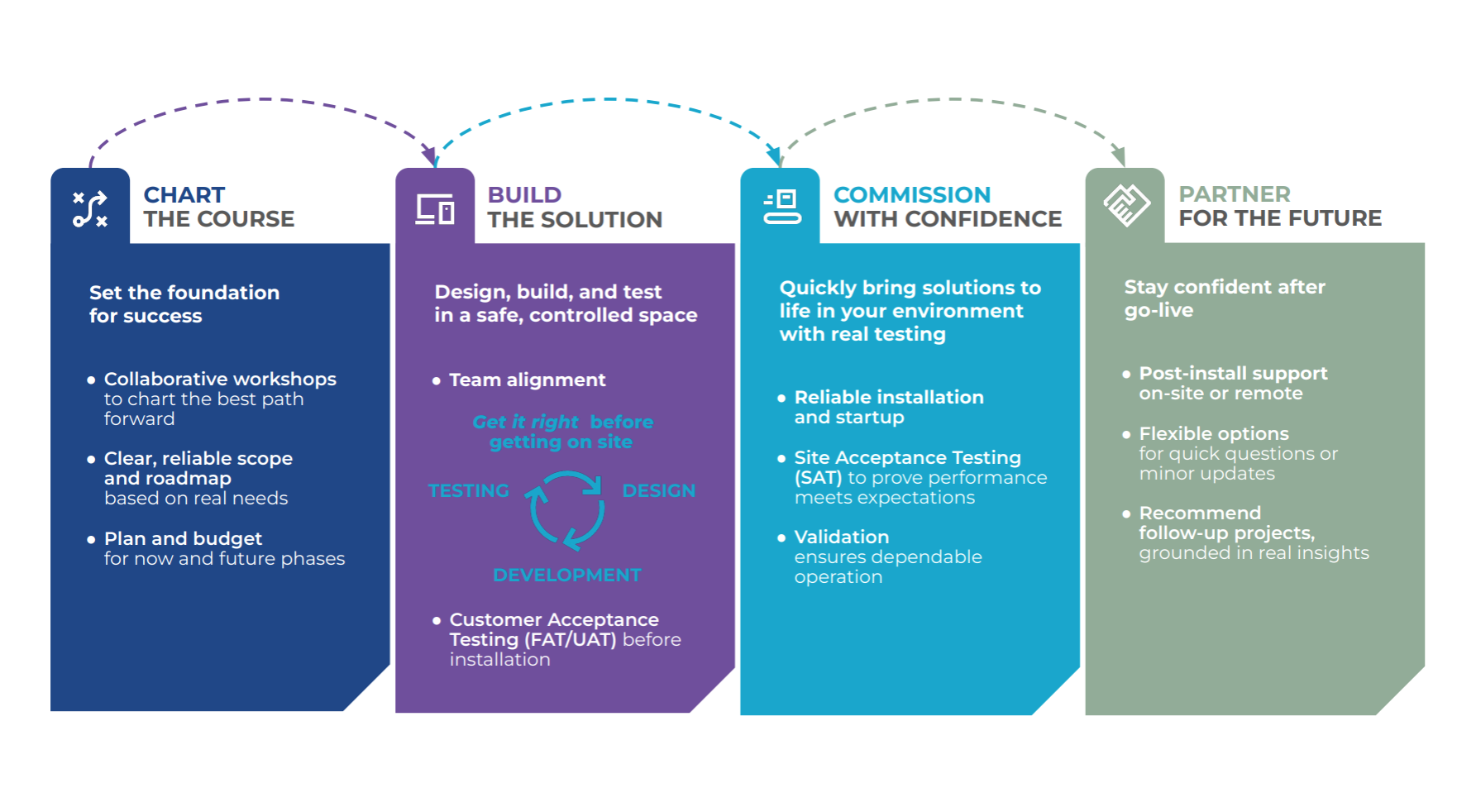

Our Proven Process

Simplifying Complexity, One Step at a Time

Every successful project begins with clarity. Our 4-step process takes the guesswork out of complex automation. By getting it right from the start, we make sure your project flows smoothly and delivers real operational impact.

Featured Insight

Jack Danielʼs Enlists EOSYS

Industries

Your Unique Challenges Deserve a Strong Foundation

Our comprehensive project methodology adapts to your operation, providing a solid foundation that keeps systems running smoothly.

Contact

Turning Complexity Into Confidence

FAQS

Industrial automation projects are hardware-centric, often waterfall-based, and focused on physical system deployment, integration timelines, and regulatory compliance.

We align with ISA-95, IEC 61131, and PackML to ensure system reliability, interoperability, and long-term performance.

Controls engineers, OEMs, plant managers, and compliance officers are key stakeholders who guide decisions and validate outcomes.

Yes. We turn compliance frameworks into executable plans that align with your timeline, system architecture, and operational goals.

Factory Acceptance Testing (FAT) validates system functionality before shipment. Site Acceptance Testing (SAT) confirms performance post-installation.

Structured project management typically involves hardware-centric planning, milestone tracking, and waterfall execution models tailored to physical system deployment.

Delays, integration failures, scope creep, and compliance gaps often stem from weak structure, poor communication, or misaligned standards.

Avoiding these requires anchoring every phase in disciplined planning. Lead times are built in early. Integration is mapped with precision. Scope is locked through shared milestones. Compliance is engineered into every decision.

That’s how systems launch clean, perform reliably, and scale without surprises.