February 20, 2026

What is Digital Manufacturing?

A connected, real‑time way to run operations with smarter automation, clearer insight, and fully integrated systems.

- Definition (Simple Terms): Digital manufacturing uses digital technologies to connect and improve production processes. It brings together physical manufacturing operations, real-time data, and automation to improve efficiency, quality, and agility.

- Key Difference: Traditional manufacturing relies on manual processes and isolated systems. Digital manufacturing creates a connected production environment and serves as a practical application of Industry 4.0 concepts on the factory floor.

- Major Benefits: Manufacturers see reduced downtime through predictive maintenance, improved throughput and efficiency, more consistent quality with full traceability, and lower waste and energy usage. These improvements enable compliance, cost reduction, and operational resilience.

- Core Pillars: Digital manufacturing initiatives focus on integrating IT and OT systems, automating and orchestrating production workflows, using real-time data for decision-making, and enabling continuous improvement across technology and processes.

- Implementation Journey: Adoption typically begins with readiness assessments and high-impact pilot projects like real-time performance monitoring or predictive maintenance. Successful pilots are then scaled and standardized across the organization. Throughout this process, experienced system integrators help connect ERP, MES, SCADA, and IIoT systems to ensure technology delivers measurable value.

The Role of Digital Manufacturing in Today’s Plants

Digital manufacturing is the integration of advanced digital processes into production operations.

It connects automation, real-time manufacturing data, and plant-floor systems to improve how work actually gets done.

What was once a buzzword is now a core operational strategy for manufacturers under pressure to improve efficiency, quality, and responsiveness.

Digital Manufacturing vs. Industry 4.0

Digital manufacturing is a core component of the broader Industry 4.0 movement. It represents the vision of smart, connected, automated industries. Digital manufacturing translates that vision into Industry 4.0 maturity on the factory floor and defines the direction. Digital manufacturing is how companies implement it in day-to-day operations.

Dispelling Myths About Digital Manufacturing

Misconceptions persist because the difference between digital and traditional manufacturing isn’t always clear. Traditional plants rely on manual steps and isolated systems; digital operations use connected data, automation, and coordinated workflows. That gap fuels the myths that follow.

✗ Myth: “Digital manufacturing is just about buying new tech or a single software.”

✓ Reality: It’s a holistic effort. It involves connecting multiple systems, reshaping workflows, and changing how teams operate.

✗ Myth: “It’s only for huge, high-tech factories.”

✓ Reality: Traditional and smaller plants can also adopt digital manufacturing. Phased, use-case driven pilots allow facilities to start small, prove value, and scale over time.

✗ Myth: “We need a massive, ‘big bang’ implementation.”

✓ Reality: A step-by-step approach works better. Organizations can focus on a few high-impact projects first, demonstrate ROI, and then expand. Digital transformation is iterative, not all at once.

✗ Myth: “Digital manufacturing will replace jobs or micromanage workers.”

✓ Reality: The goal is to augment workers by reducing low-value manual tasks and giving employees better information to help decision-making.

Why Digital Manufacturing Matters

Digital modernization gives manufacturers the leverage to run operations with more speed, stability, and clarity.

It drives manufacturing efficiency improvement by reducing hidden losses, tightening workflows, and giving teams real‑time visibility into how production is performing. Connected systems also enable predictive maintenance manufacturing, helping plants prevent failures before they happen and protect uptime.

Together, these capabilities strengthen daily operations and deliver measurable financial impact across the organization.

Core Pillars of Digital Manufacturing

Companies that succeed treat digital tools as part of a larger operational shift, not as isolated upgrades. They focus on the structural elements that enable teams to share information, coordinate work, trust their data, and improve performance through discipline. These pillars give every initiative a stronger chance to scale and deliver measurable results.

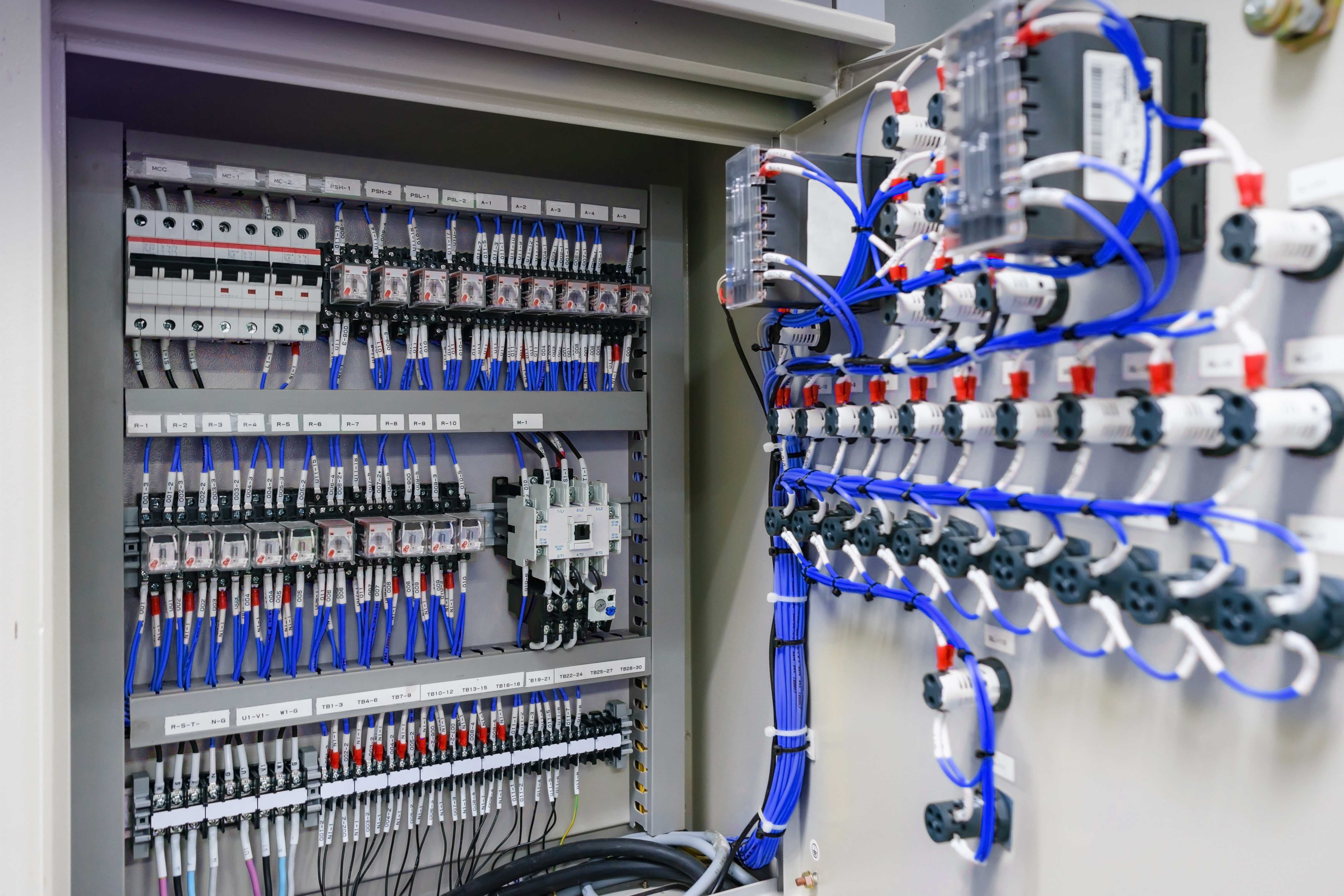

Integration and Connectivity  (IT-OT Convergence)

(IT-OT Convergence)

Breaking down data silos is often the first step. Connecting information technology (IT) systems with operational technology (OT) on the plant floor creates a unified data environment linking machines, production lines, laboratories, and quality systems. This integration helps end-to-end visibility of assets and processes.

Automation and Orchestration

Automation and Orchestration

Digitally orchestrated production goes beyond isolated automation cells. Machines, people, and processes are coordinated into cohesive smart automation ecosystems. Standard procedures are automated and enforced consistently across lines and plants.

Data-Driven Decision Making

Data-Driven Decision Making

In a digital plant, decisions at all levels are informed by timely, accurate data. Key metrics are captured continuously and shown through dashboards and alerts. Rather than relying on delayed reports or intuition, teams use live data to guide actions.

Continuous  Improvement Culture

Improvement Culture

Leading firms treat digital manufacturing as an ongoing journey. As technology and business needs evolve, teams continuously adapt by running small pilot projects, validating results, and scaling successful solutions.

Who Benefits Across the Organization

Digital manufacturing strengthens performance across the enterprise. Each team gains clearer information, faster feedback, and more predictable operations. Leaders see how plants run in real time. Frontline teams spend less time chasing data and more time solving problems. IT and operations work from a shared source of truth.

This shift also brings teams closer together. Digital systems link functions that once worked apart, which makes coordination and steady change essential.

Role |

How digital manufacturing helps |

| Plant Managers / Operations Managers | Higher equipment uptime and smoother production, with improved OEE and reduced downtime. Predictive maintenance identifies issues before failures occur, helping reduce unplanned downtime. Real-time manufacturing data improves resource allocation and reduces day-to-day firefighting, improving safety and output. |

| VPs of Manufacturing / Transformation Leaders | Scalability, standardization, and measurable ROI. Access to consistent data helps quantify improvements and replicate successful initiatives across sites, supporting long-term competitiveness through digital manufacturing. |

| Quality & Compliance Managers | Automated, reliable data collection across batches and products. End-to-end traceability with less manual recordkeeping. Real-time quality metrics and digital batch records enable audit readiness, faster issues isolation, and more efficient compliance reporting. |

| CIO / IT-OT Integration Leaders | Secure connectivity between shop-floor and enterprise systems while maintaining cybersecurity. Emphasis on interoperability across ERP, MES, SCADA, and IIoT, along with data governance and infrastructure that supports analytics and cloud services. |

By connecting traditionally separate IT and operations domains, digital manufacturing increases the need for cross-team collaboration. Clear vision and change management from the outset are essential.

Industry Applications and Use Cases

Industries adopt digital manufacturing to solve the problems that define their operations. Some need tighter batch control.

Others need steadier lines, cleaner data, or faster root‑cause analysis. The examples below highlight how these needs drive different applications across process and discrete environments.

Food & Beverage, CPG

Use cases include recipe consistency, throughput, labeling compliance, and end-to-end traceability.

A CPG firm connects batching, lab, and packaging systems through MES to detect out-of-spec product and automatically place holds before packaging.

Outcomes: Less rework, fewer complaints, reduced waste.

Explore: Food/Beverage | CPG

Chemicals, Spirits

Focus areas include precise formulations, safety, regulatory record-keeping, and batch control.

A spirits producer digitized batch records and automated setpoints, improving batch consistency and reducing downtime.

Outcomes: Improved quality, fewer off-spec batches, higher uptime.

Pulp & Paper, Metals

Key needs include asset performance, energy optimization, and production scheduling.

A metals facility linked furnace predictive maintenance with energy management to align maintenance with planned downtime.

Outcomes: Avoided breakdowns, lower energy waste, improved reliability.

Explore: Pulp & Paper | Metals

Automotive

Applications include flexible production lines, component traceability, quality analytics, and proactive maintenance.

An auto parts plant captured station-level quality data to trace defects to specific machines and settings.

Outcomes: Fewer defects, faster root-cause analysis, smoother changeovers, reduced downtime.

Explore: Automotive

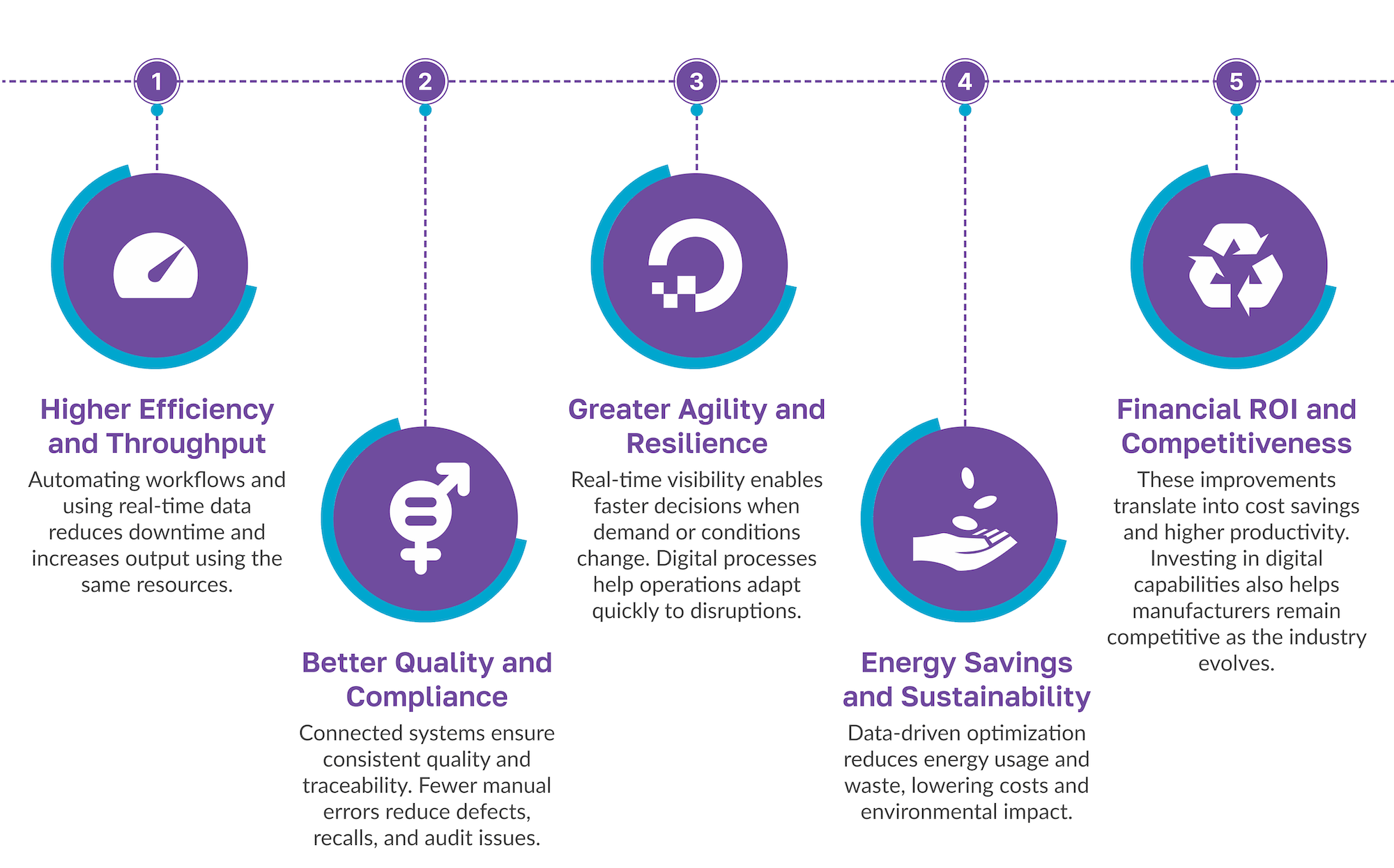

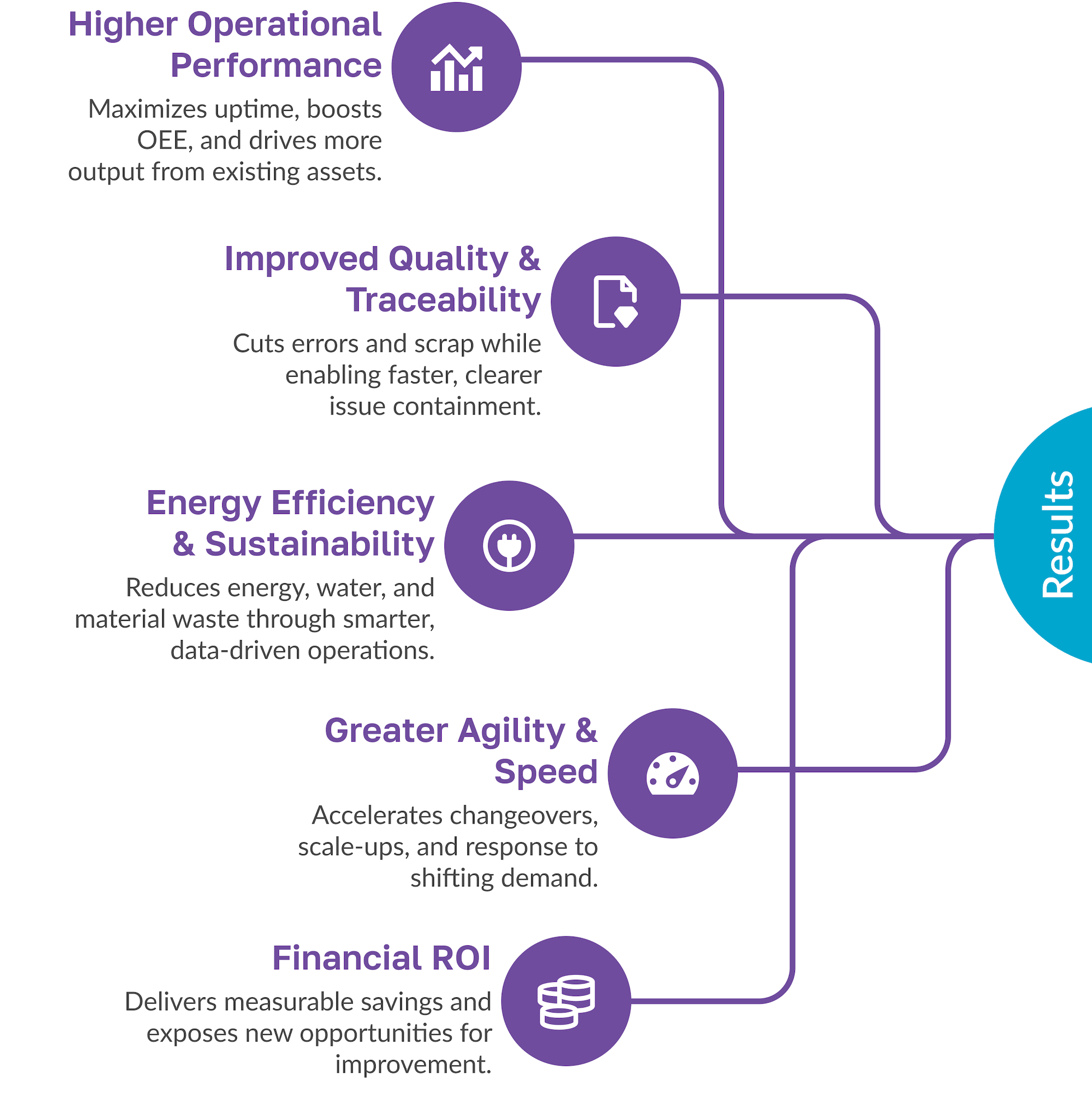

Business Outcomes That Matter

Companies invest in digital manufacturing to deliver results that show up in daily operations and long‑term performance.

Plants run more reliably.

Quality improves.

Resources stretch further.

Better data and connected systems give teams the leverage to cut waste, speed decisions, and raise productivity in ways leadership can measure.

The outcomes below reflect the gains organizations look for when they modernize their operations.

The Digital Manufacturing Journey: From Pilot to Transformation

Manufacturers rarely transform in a single leap. They move step by step, building confidence as they modernize equipment, connect systems, and prove out new ways of working.

Early projects reveal what the data can unlock.

Later phases focus on scaling what works and creating the structures that keep progress moving. The path is deliberate, and each stage strengthens the next.

1. Assess and AlignBegin with an assessment of the current state including IT and OT architecture mapping, system interoperability, and data readiness. Align on business objectives to prioritize use cases that deliver meaningful value. |

2. Implement High-Impact Use CasesStart with a small number of high-impact projects, such as digital quality workflows, traceability, and genealogy systems, that address priority pain points and have clear ROI. These efforts are often piloted on a single line. |

3. Scale and StandardizeSuccessful pilots are then expanded across lines, plants, or functions. This phase focuses on standardizing architecture and governance to enable efficient solution replication. Common data models, shared platforms, and deployment templates help standardize proven processes. |

Throughout this journey, having the right expertise is critical. Many manufacturers work with specialized integration partners to accelerate implementation and reduce risk. Integrating ERP, MES, SCADA, and IIoT systems requires careful design to ensure reliable data flows and alignment with operational needs.

How an integration and orchestration partner like EOSYS supports this effort.

- Integration and Architecture: Designing IT/OT architectures that connect shop-floor systems through MES to ERP and cloud analytics.

- Implementation Services: Conducting assessments, developing digital manufacturing roadmaps, and executing hands-on integration across platforms, automation systems, sensors, and analytics tools.

- Domain Expertise and Change Management: Applying industry-specific knowledge while helping alignment between IT and operations teams through training and change management.

Choosing the right partner reduces risk, accelerates time to value, and enables a cohesive digital marketing strategy.

The Future of Digital Manufacturing

Digital manufacturing continues to play a central role in modern manufacturing strategies.

Companies investing in these capabilities are building a stronger foundation for Industry 4.0 maturity and long-term operational improvement.

Adoption is expanding beyond large enterprises as solutions become more modular and accessible for small and mid-sized manufacturers.

As technologies evolve, digital manufacturing remains a continuous journey focused on improving agility, efficiency, and operational performance.

Organizations looking to advance their digital manufacturing initiatives often work with experienced partners.

Firms like EOSYS help manufacturers in implementing, scaling, and sustaining digital manufacturing programs across operations.

FAQs

Digital manufacturing uses data, software, and connected equipment to improve how factories operate. It connects production steps through technology to make processes more efficient, flexible, and accurate.

It works by integrating shop-floor technologies like sensors, control systems, and software platforms. Equipment generates real-time data, systems analyze that data, and insights are used to optimize performance or alert teams to potential issues.

Industry 4.0 describes the broader vision of smart, connected, automated industries. Digital manufacturing focuses specifically on applying those digital technologies within manufacturing operations.

Organizations typically begin by assessing current systems and identifying one or two high-impact use cases. A focused pilot with clear success metrics helps validate value before broader rollout.