October 2, 2025

SCADA: The Technology Behind Safer, Smarter, More Efficient Industrial Operations

SCADA gives organizations real‑time visibility, safer operations, and stronger control across complex industrial systems by turning equipment data into clear insight and actionable decisions.

What Is SCADA?

SCADA, which stands for Supervisory Control and Data Acquisition, is a control system designed to collect key data from industrial equipment. It is a combination of SCADA software and hardware that enables industrial process automation by capturing operational technology (OT) data in real-time across various industries.

A SCADA system connects sensors that monitor valves, pumps, and motors, allowing them to be monitored either onsite or remotely. It is essentially a system that enables large-scale processes and remote monitoring.

How SCADA Works: A Basic Breakdown

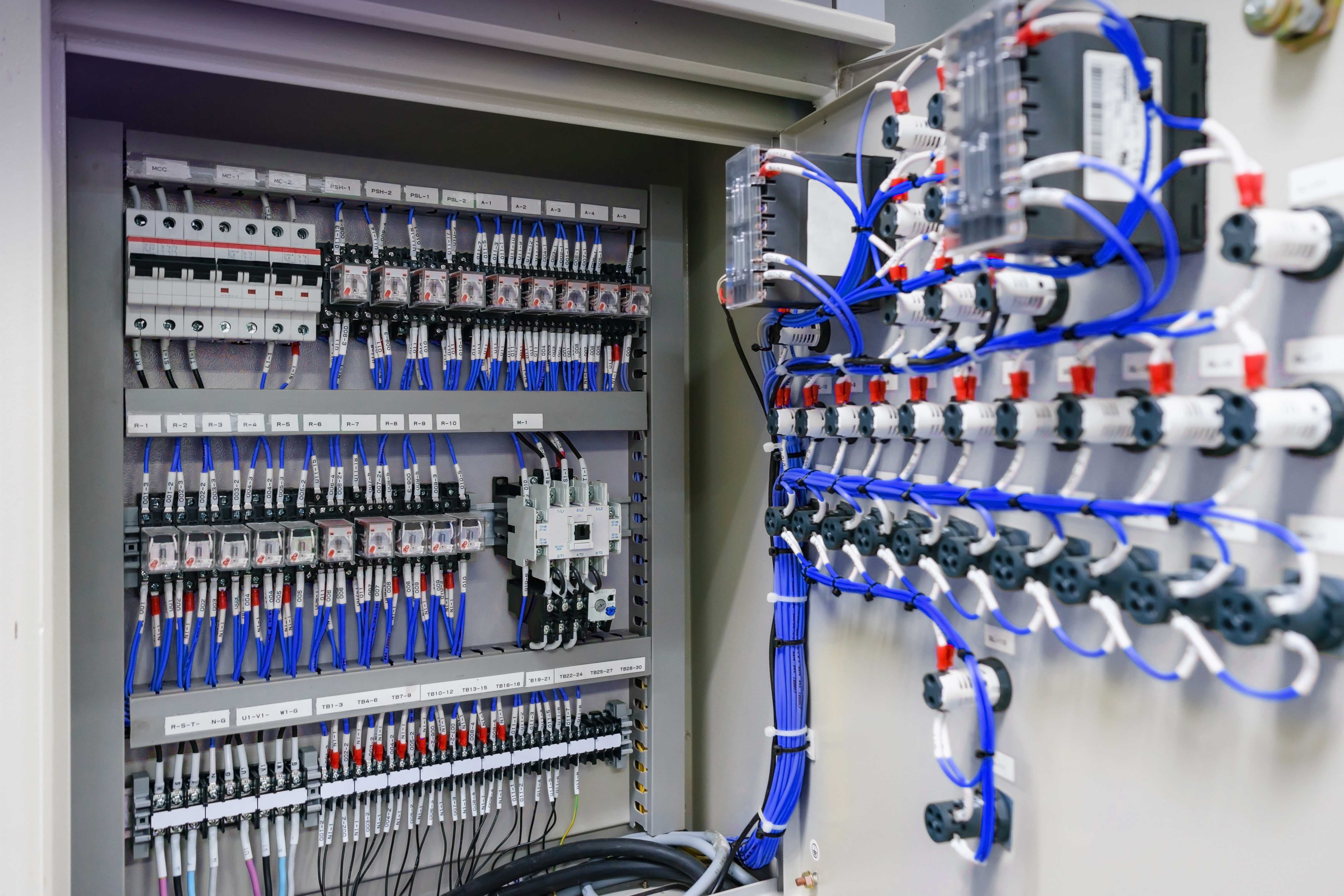

SCADA serves as a central nervous system for an industrial control system, effectively bridging the gap between field devices and decision-makers or operators within a company. It is designed to integrate through automation solutions and programmable logic controllers (PLCs). Here’s a breakdown of how it works:

- Sensors and PLCs or RTUs: Sensors are placed at various locations to gather data from machinery like valves and pumps. This data is collected by PLCs or remote terminal units (RTUs), which act as intermediaries by sending information to a central location.

- Central Server Communication: The collected data travels from PLCs or RTUs to a central server through wired or wireless communication networks.

- HMI (Human-Machine Interface): The software processes and organizes the data and displays it in a user-friendly format called an HMI screen. This screen provides a visual representation of the system, allowing operators to see what is happening with machinery or equipment in real time.

- Analysis and Control: Operators monitor the HMI screen for key information and send commands from the same interface to control equipment remotely. For example, they may turn a pump on or off.

- Logging and Alarms: The SCADA system records data and events, creating logs for future analysis. Modern systems can also trigger alarms or notify operators when specific events occur, such as when a tank level becomes too high or too low.

Key Functions & Features of Modern SCADA Systems

At its core, a modern SCADA system enables organizations to:

- Acquire, analyze, and display real-time data

- Control processes locally or from a remote location

- Interact directly with industrial equipment such as motors, pumps, valves, and sensors

- Record and archive events for future reference or reporting

- Help alarm management and system monitoring with security features

- Integrate with other systems like distributed control systems (DCS) or PLCs

Use Cases & Industries That Can Benefit From SCADA Systems

Many industries benefit from SCADA-backed automation solutions. Sectors like energy, water and wastewater, oil and gas, pipelines, and manufacturing rely on SCADA for cross-site monitoring and control. SCADA provides real-time visibility, facilitating efficient operations and informed decision-making.

When used as part of a broader automation strategy, many businesses report improved efficiency and reduced downtime. Below are some real-world examples:

- Oil & Gas: SCADA is widely used in the oil and gas industry as a key component of process automation. Even one hour of unplanned downtime can cost thousands of dollars. SCADA allows energy system operators to monitor flow, pressure, temperature, and tank levels remotely, reducing the need for on-site intervention. Systems can also be programmed to shut down equipment automatically if unsafe pressure levels are detected, improving worker safety.

- Water/Wastewater: SCADA is commonly used by water and wastewater utilities and power grid operators. Cities may use SCADA to optimize traffic patterns, power consumption, and water distribution by monitoring control systems and identifying usage trends. This data helps operators anticipate periods of increased demand and prepare infrastructure accordingly.

- Manufacturing: SCADA systems enable the safe and efficient operation of machinery in manufacturing environments. They can help predict maintenance needs and adapt maintenance schedules as equipment performance changes. This helps avoid unplanned shutdowns and production bottlenecks. SCADA systems can also monitor operating conditions and shut down equipment if it is not functioning optimally, helping prevent further damage.

Advantages & Limitations

SCADA systems offer several advantages, along with some limitations. Understanding both can help companies determine whether SCADA is appropriate for their operations.

- Advantages: SCADA offers remote control options that allow one worker or operator to monitor multiple pieces of machinery or areas, reducing the need for additional employees or enabling them to perform other tasks instead of monitoring machinery. It also offers scalability and flexibility, meaning companies can tailor it to their needs and preferences. This is important, as no two businesses and their operations are exactly alike. It also provides centralized visibility.

- Limitations: Because SCADA works remotely and utilizes wireless or wired connections, it can have latency issues or concerns related to network reliability, as it relies on remote or public communication infrastructure. As with any such system, there is also a security risk from potential hackers or malicious actors.

SCADA vs DCS & HMI

In some cases, SCADA can be used in conjunction with DCS or HMI systems to enhance what can be controlled and monitored, while also making operations more user-friendly.

Generally, SCADA systems are designed for large-scale remote monitoring and control. Conversely, DCS is more applicable for local processes or more complex operations. An HMI is the user interface that can work with either scenario.

Another way SCADA and DCS differ is their focus. SCADA is focused on data gathering across wide areas, creating a broad operational picture that can involve multiple plants or companies.

DCS is more focused on intricate processes and is usually designed for use within a single plant. Therefore, SCADA is often the better option for large companies with geographically distributed operations, while DCS is typically better suited for real-time control or complex systems within a single facility.

As a result, the choice depends on the size and geographical layout of a company. There are advantages and disadvantages to both, but scale and physical layout are key factors in choosing between them. SCADA can also be customized for specific purposes, which provides additional flexibility.

How EOSYS Designs SCADA Solutions

At EOSYS, we are invested in your success. As such, we design SCADA solutions for various industries, focusing on scalability, dashboard design, cybersecurity, architecture, and redundancy to meet unique operational requirements across applications.

We are also committed to implementing reliable SCADA systems that are thoroughly vetted for network security, operational reliability, teachability, and ease of use for ongoing maintenance and training.

We partner with our clients to provide best-in-class solution services tailored to their needs. Our methodology, dedication, and attention to detail generate lasting results.

Strengthen Your Operations With Smarter SCADA?

There are many advantages to implementing SCADA software, especially for large-scale operations that span multiple geographical locations. SCADA systems are designed for this purpose and help keep machinery operating optimally while creating safer working environments. At EOSYS, we are committed to delivering technical solutions that automate, monitor, and secure industrial systems. We are an employee-owned company, and our team members are personally invested in each client’s success.

EOSYS is ready to help create automation solutions that streamline workflows and create safer working environments.

Contact us today to learn more.

SOURCES

https://www.onlogic.com/blog/what-is-a-scada-system-and-how-does-it-work/

https://automationelectric.com/scada-vs-dcs-choose-the-correct-control-system-for-your-needs/

https://www.vartechsystems.com/articles/the-financial-cost-of-downtime